What does the future of food manufacturing look like? If the past few years have taught us anything, it isn’t as easy as gazing into a crystal ball, but trends have emerged that are giving us a better idea of what the next ten years might look like.

Industries across the board have adapted to meet new customer demands and keep up with current trends. As customers have become increasingly home-bound and stopped eating out at restaurants, the food manufacturing industry needed to undergo rapid changes to keep up with a new demand for groceries. But as we return to indoor dining, manufacturers are starting to plan ahead for long-term sustainability, profitability and a growth-oriented infrastructure.

The future of food manufacturing in the next ten years hinges on maintaining a growth-oriented mindset, while promoting sustainable practices and plant-based foods. Here are our predictions on the future of food manufacturing, and how your business can facilitate long-term success to 2030 and beyond.

Expanding Infrastructure

As the demand for groceries has grown in the last few years, the demand for manufacturing infrastructure has also increased. In fact, according to an analysis done by Food Dive, “more than 70 manufacturing expansions have been announced or completed this year.” This radical expansion comes on the heels of a slow decline in the manufacturing industry, where many businesses were experiencing a lack of growth and undergoing cost-cuts to stay afloat.

According to Food Dive, the dialogue surrounding the manufacturing industry has undergone a drastic transformation as well. A few short years ago “companies had seen flat growth, leading to job cuts, factory closures and painful restructuring in the name of saving money,” and because of this, “Wall Street wanted food businesses to make those kinds of cuts to hold its bottom line.” Now, the new demand for groceries has revitalized businesses across the country, and Wall Street has started to encourage businesses to invest in infrastructure for the future.

Adapting to New Demands

Investing in infrastructure primarily contributes to increased production, but it also allows companies to reconfigure their products to meet current demands.

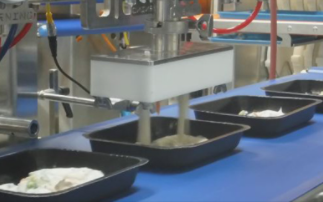

Individual Packaging

Increased awareness regarding viral spread and public health has emerged over the past several years. Because of the new attention to health and safety, food manufacturers have also seen increased demand for individual packaging. Snacks that were once served from a large communal bag are more popular when sold in individual-sized packages. This type of packaging requires alternate manufacturing equipment, designed to produce smaller portions while still keeping up with high demand.

Increased Health and Safety

To mitigate risks during the manufacturing process, more facilities have adopted increased health and safety protocols. This includes infrastructure within the facility to provide end-to-end product traceability, so products are monitored at every stage of the production process.

Additionally, manufacturers are investing in increased resources to promote employee health and wellness such as hand washing stations and improved ventilation. These changes encourage a safe environment for workers dealing with raw materials and minimize illness and injury.

Growing Sustainably

In addition to more individually packaged foods, manufacturers have seen a sharp increase in demand for plant-based products. From meat-alternatives like burgers and sausages to plant-based snack foods and desserts, consumers are more conscious of their diet and their impact on the planet.

A Food Dive article exploring the prevalence of plant-based products in manufacturing claims that “if plant-based meat alternatives continue to expand at their current rate, they will represent 6% of total meat consumption by 2030.” This means that producers would need to put out “25 million metric tons of products per year” to keep up with the demand.

The increased popularity of plant-based foods means that manufacturers need to start incorporating plant-based options into their product base. This transition starts with exploring alternative protein sources, anticipating supply-chain issues, and acquiring new equipment. The aim for manufacturers is to stay ahead of the curve and provide customers with products they desire both now and in the future.

Building Your Facility with Quantum

Investing in the future means creating a facility that’s built to last. Here at Quantum, our team of experts are here to help you find elegant, efficient, sanitary solutions for your manufacturing needs. Our custom-built equipment is made from high-quality materials, and designed with attention to detail. Plus, our in-house fabrication capabilities allow us to cut back on production time, and provide fast, budget friendly, quality results to all our customers. Contact Quantum today to set up your first consultation!