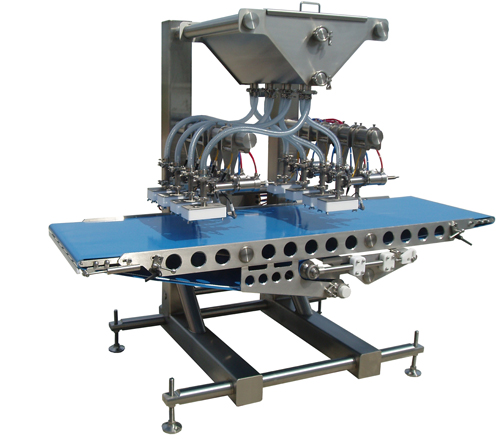

CONVEYORIZED TARGET SAUCE APPLICATOR

Model # QTSA Series

USDA approved patented sauce applicator, capable of evenly applying sauce to your product while maintaining a sauce free border. Our CONVEYORIZED TARGET sauce applicator is a simple, easy to use system ideal for depositing sauce onto panini, sandwiches, and French bread products. Products are precisely located under the applicating head by means of our continuous motion conveyor. Sauce is automatically applied to the product as it passes below.

PRODUCT:

Pizza Sauce, BBQ Sauce, Cheese Sauce, Ranch Dressing

SAUCE HOPPER:

40 Gallons with Hinged Removable Lid

UTILITY REQUIREMENTS:

200-240 VAC., 3 Phase 5 Amp Circuit 50/60 Hz

380-480 VAC., 3 Phase 4 Amp Circuit 50/60 Hz

Other Voltages Optional

80 PSIG @ 15 SCFM Clean Dry Air

PRODUCTION RATES UP TO:

Up to 100 12” Pizzas Per Minute, Per Lane

OPTIONS:

High Capacity Hopper Transfer Pump

Circle Feeder